News and Information

RIVER AVICH HYDRO COMMUNITY BENEFIT FUND

AED donates £100,000 to the Community Benefit Fund in 2024.

Jan 21 2025 - Board sets date for AGM 2025

During the January meeting of the Board, our directors agreed the date for the 2025 AGM.

The meeting will be held online on Saturday 31st May at 11am. Details and documents will be sent to our

members in due course.

Once again we will be looking for new blood to join our current board. Meeting once a quarter on Zoom, you can join us from anywhere. If you are someone who has a finance head, a business management head, a keen interest in renewable energy projects, a passion for sustaining rural communities!

If yes, you could help take Awesome Energy into the future.

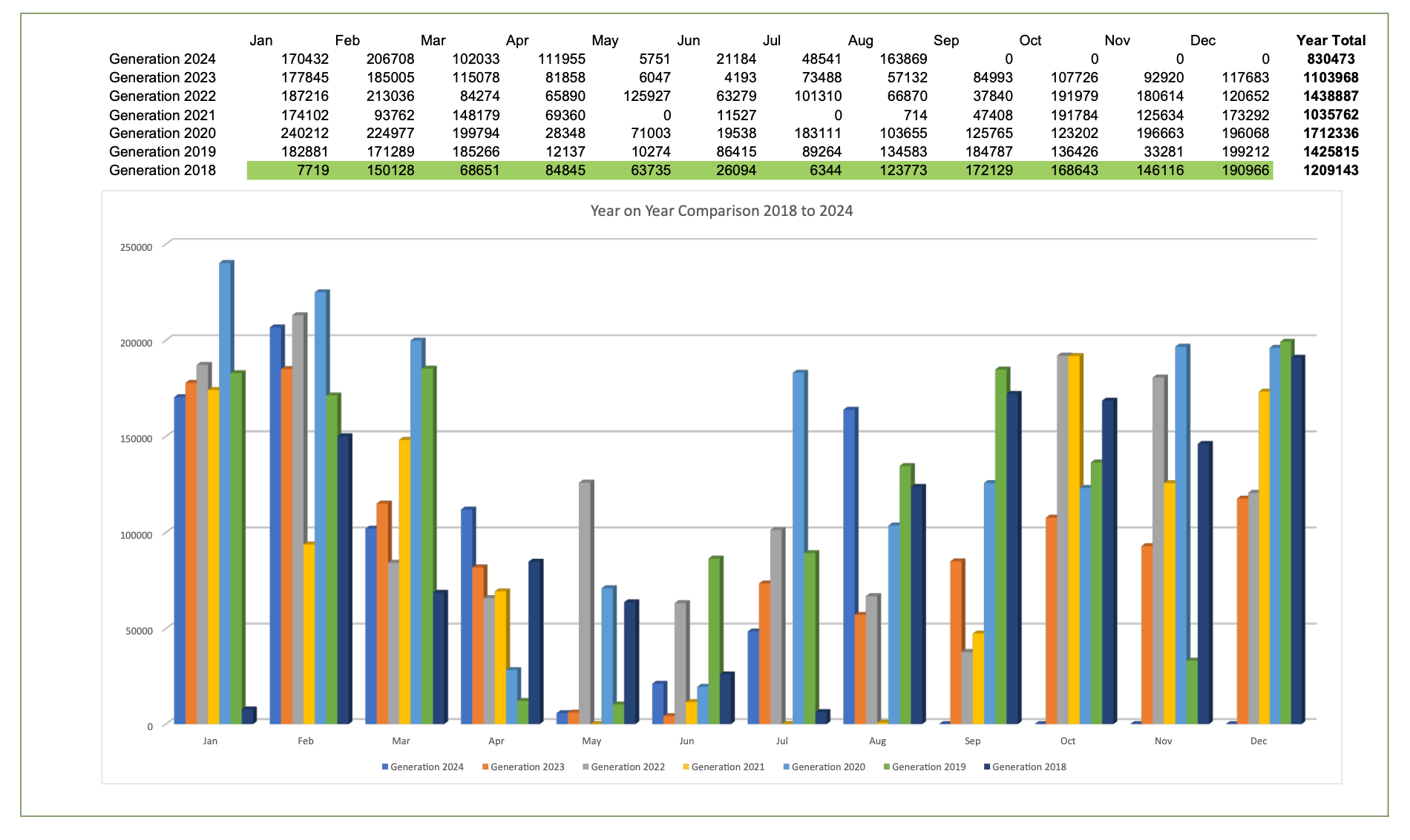

September 2024 - Record Generation figures in August

After a very dry summer the heavens decided to open in Argyll, and it rained and rained, and rained some more. The river was high, keeping the turbine busy on most days, which brought our generation in at 163,869kWhs. At 178.5% of target we recorded our best ever August since generation started in 2018.

May 11 2024 - AGM awards Community Benefit Fund payment £100,000

During the meeting of the shareholders at our AGM held Saturday 11th May 2024, the members approved a further payment of £100,000 to our Community Benefit Fund (RAHCBF).

For more details of how the fund is managed and helps the local community see the latest River Avich Hydro Community Benefit Fund report from our Fund Managers Foundation Scotland.

February 27 2024 - AGM Calling Notices.

First calling notices have gone out to our shareholders today, via email or post. If you are a shareholder and have not received your notice please contact the Hydro Team as quickly as possible.

Registration for the Zoom meeting is now open, link has been sent direct to Shareholders.

October 2023 - Heavy Rains halt Generation

Normally, heavy rain in Argyll is good for our the river flow, our water levels and therefore good for generation and revenue. However, as they say more is not always a good thing.

Overnight 6th to 7th October heavy rains hit Argyll whilst storms battered the East Cost of Scotland. Heavy rain is good for generation, but with roads flooding, landslides occurring, and trees losing branches as well as their normal leaves, some times rain can be too much too quickly.

With water levels rising our turbine was operating at full capacity, drawing water from the river to our intake at a more powerful flow than the river. Unfortunately this also brought with it a higher than normal amount of debris, which caused the intake to block. The build up is very fast in storm conditions and with high water although river flows are high the depth means that flow rate at the screen is very slow and leaves will not clear significantly. As a result although the turbine attempts to restart it quickly shuts down again.

With water levels so high and flow so fast it was not safe to allow any of the Ops team to enter the river to clear the intake. The turbine has a safety feature that will only allow a set number of emergency stops and starts before a complete shut down occurs. However even from the online data it was clear that we wouldn’t be able to run in the immediate future and our operations Director therefore took the sensible decision to turn the turbine off until the river and rainfall returned to more normal levels. This action ensured that on the first available day Peter and his team were able to check the turbine, and safely restart it with no damage or problems other than a few large branches to clear. Huge volumes of stones moved down river and some redistribution of the river bed occurred as well as some small stones blocking the screen these were cleared. When the level dropped still further we were able to clear the compensation slot of branches and ensure we maintained compliance with our SEPA license.

AED are very grateful to have a local team of trained people, who can ensure quick responses and the safe efficient running of our Hydro scheme.

Taking Awesome Energy Forward

Our current board of Directors are planning for the future

The project development and build was a phenomenal achievement, and our Hydro has now been generating for five years, exceeding forecasted generation in four out of those five years

Now Awesome Energy is moving into a new phase.

Maintaining the operational effectiveness of the plant, ensuring the benefit(s) we can bring to our Community, protecting and safeguarding our environment.

We are looking for people with business management skills, high level financial skills, or PR skills, (to name a few) who have an interest in Enviromental and Community Issues to help take Awesome Energy forward.

If you think you, or someone you know could be the person our Board is looking for, and would be interested in joining our existing Board then we would like to have a chat with you. Send us an Email and one of our team will give you a call.

Annual General Meeting 2023

Another successful AGM held this year, with great participation and some interesting questions from the floor. Draft minutes will be available to Members, once passed by the board, and answers to questions raised will be answered on our website and in email responses to the membership. Thanks to all our Members who were able to attend, to those who kindly sent their apologies, and to those who returned their ballot papers.

During the meeting the minutes of the AGM 2021, and the Accounts for year ending 30th November 2011 were approved. Signed copies of the minutes, and signed copies of the accounts will be available for download from the Company Information pages.

During the meeting the members voted to approve the following resolutions:

- To make a 4% interest payment to all shareholders

- To make a £100,000 payment to the Community Benefit Fund

The Meeting also approved the nomination of Patrick Marshall to the Board of Directors, AED are delighted to welcome Patrick (or Roo) to the Board.

Following the meeting, one of our members, David Wilkinson answered Sam's call and offered his services. The Board quickly responded, and David has now been co-opted as a Director for the following year.

Both Patrick and David can be found on our AED Board Members page

3rd February 2023

Annual General Meeting

The date for this year's Annual General Meeting has been set and will be held online on Saturday 20th May, starting at 11am.

AGM report, Annual Accounts, Director Nominations, and invites to attend are all being prepared and will be issued to all members as soon as they become available.

The meeting will start online at 11am, and is expected to last for around one hour.

1st February 2023

Year End November 2022. Exceeding Expectations

Forecasting Rainfall can be tricky

Hot summers, low rainfall, high winds, heavy leaf falls. Freezing temperatures, frozen water.

There are many challenges to keeping our Hydro running and our Generation at maximum output possible.

Our local Operations Team, Peter, Bill, Sid, Roger & Callum worked well and effectively to keep the Hydro working at optmum output well and effectively to keep our generation as high as possible for the prevalent conditions.

Our Board of Directors based our financial forecast on Low Flow Data p50, and are delighted to announce year end generation at 130% of our target.

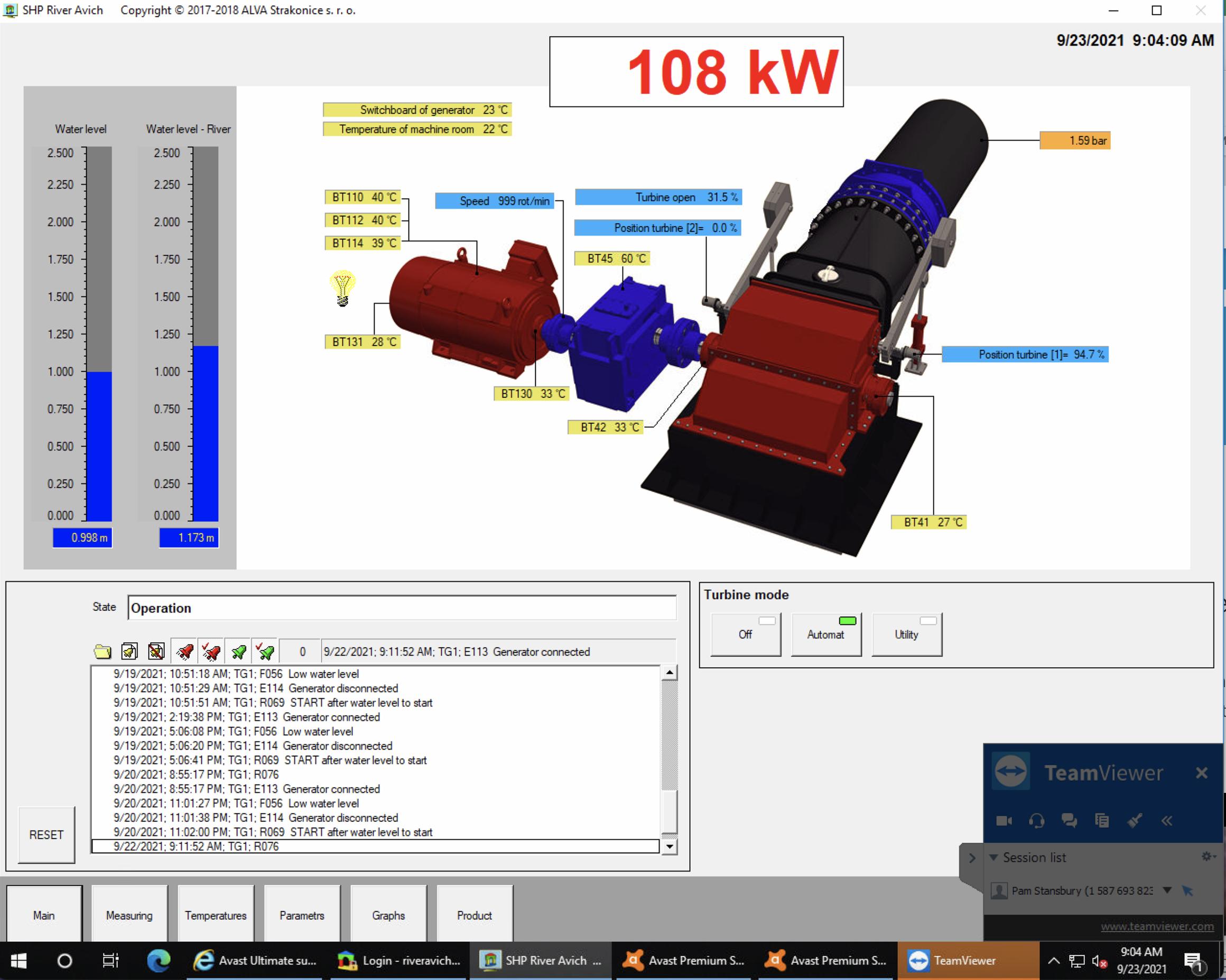

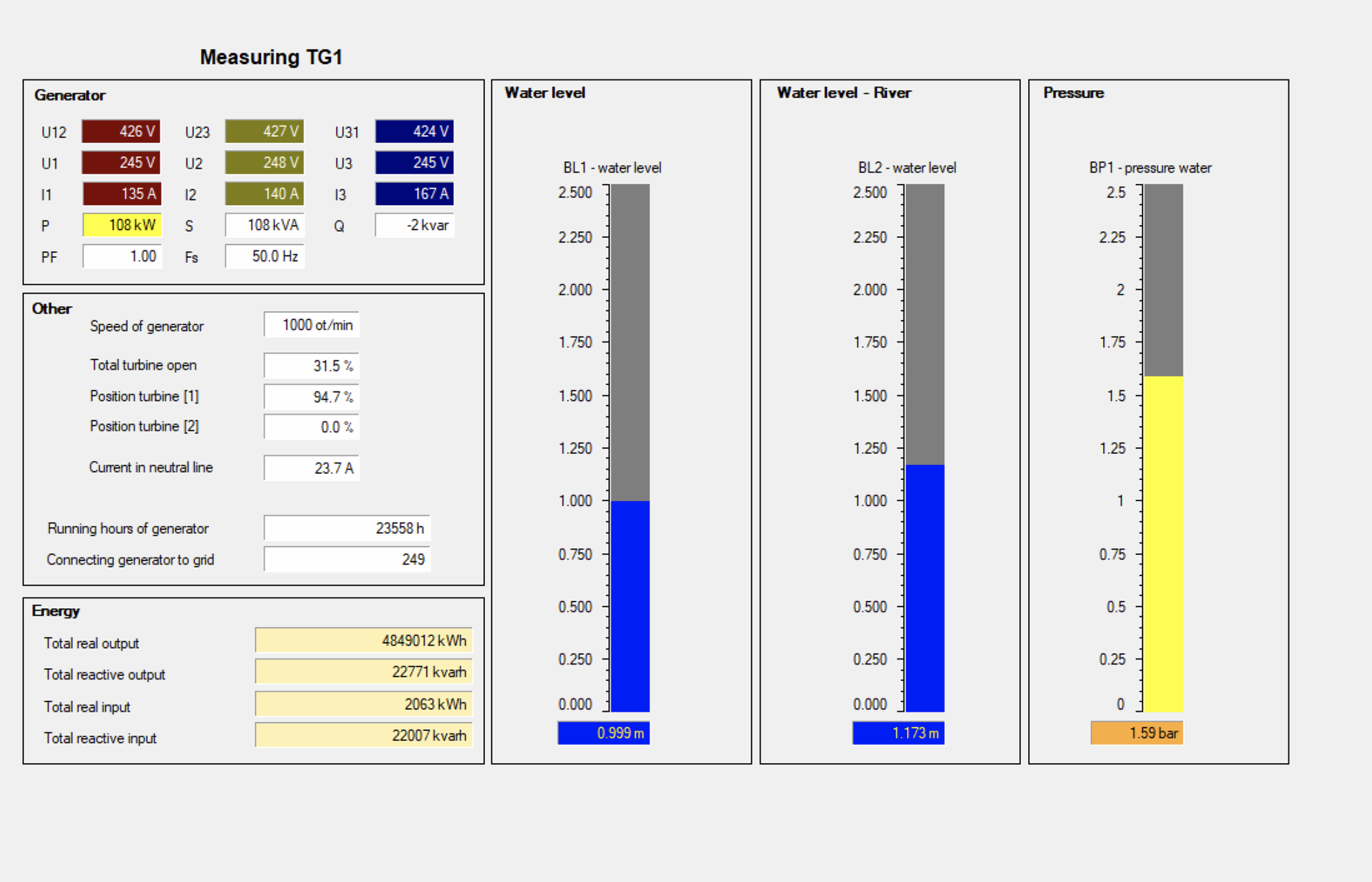

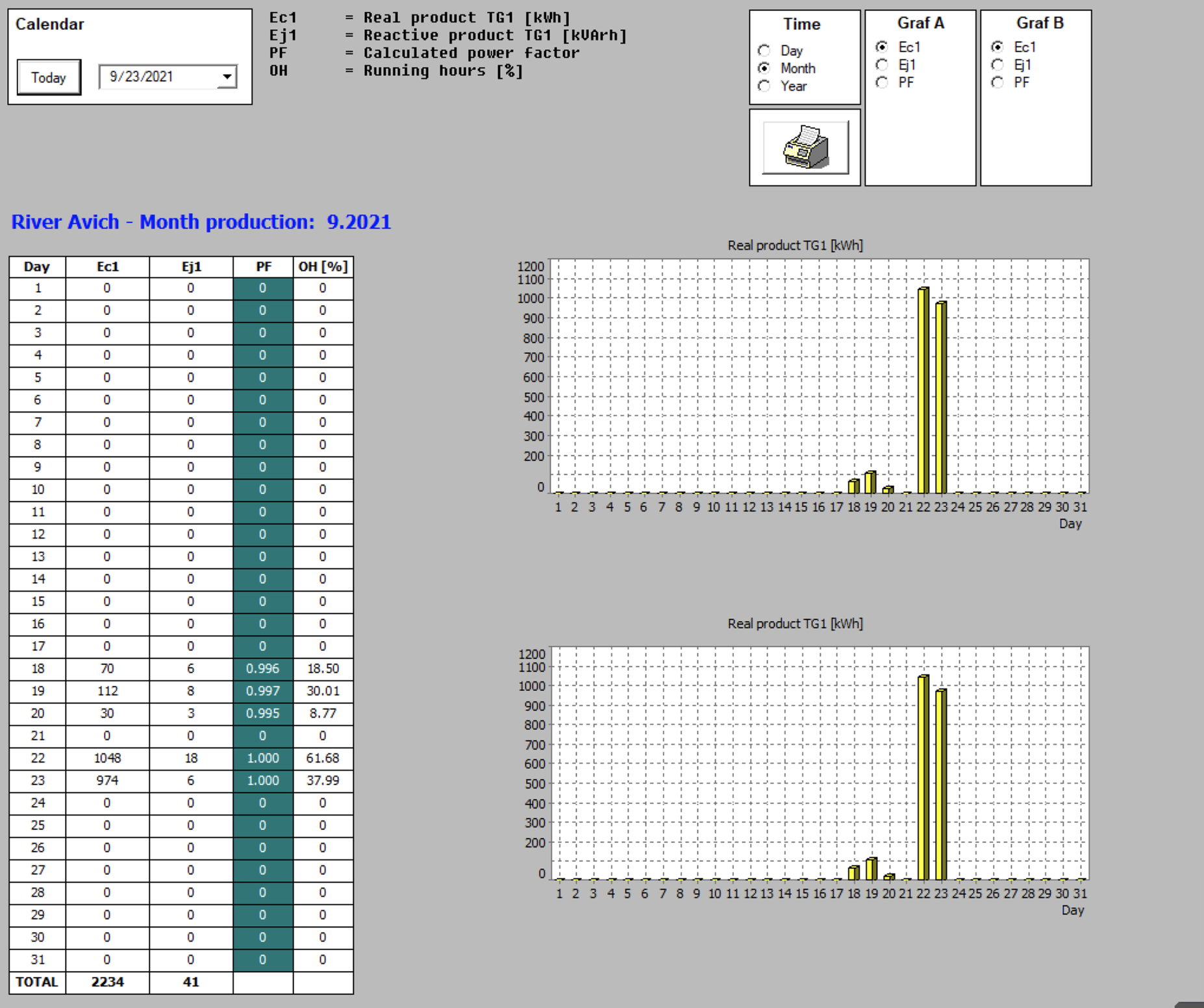

23rd Sept 2021

Dry Spell Ends

At 11:00 yesterday morning, the generator kicked into life and we started generating at 14kW; by 15:15 we were up to 80kW and she closed the day at 1048kWh. As at 11:15 today we have banked 1200kWh and are running at 105kW.

Month to date is sitting at 2462, which is small beer so far but it is predicted to keep raining for a couple of days, so we may see a semi-decent month end - perhaps 25000kWh, maybe more but keep your fingers crossed.

August 2021

Registered Company Address

Our Registered Company address has been changed from c/o The Post Office, Dalavich, Taynuilt, Argyll PA35 1HN to The Old School, Dalavich, Taynuilt, Argyll PA35 1HN.

This change has been implemented to streamline our administrative procedures, and ensure prompt attention to all received communication.

Our contact telephone numbers and email contacts remain unchanged.

1st June 2021

Annual General Meeting 2021

Our Annual General Meeting was successfully held on the 15th May 2021, via Zoom, and we would like to thank all shareholders who were able to join us for our second virtual Annual General Meeting.

The approved documentation from the Annual General Meeting is now available on our main website for all shareholders and interested parties. These can be located on our Company Information page.

13th May 2021

Generation Data April

Following a dry spell mid April we had to manually shut down the Turbine for lack of water on the 20th, and therefore did not hit our taget for the month. However we are still on course to hit (or exceed) our annual target for energy generated.

The generation data information will be published to our website following our Annual General Meeting on the 15th May.

However, the good news is that, as in previous dry spells the water supply to the community is unaffected.

13th April 2021

Generation Data March

Generation Data to the end of March is now avaiable to view and download on the website. Generation Data

Despite not hitting target in February we are still ahead on our cumulative projected target and our monthly targets for the amount we are generating

13th April 2021

2021 Board Nominations

The date for nominations to the Board of Directors for our AGM to be held on 15th May 2021, has been extended. Nominations may now submitted until 16th April 2021.

If you are interested, please write a couple of paragraphs about your background and send this, along with a photograph, to info@awesome-energy.com.

2nd April 2021

AGM 2021 Board Nominations

Our AGM has been set for 15th May 2021. In accordance with our Rules, we must elect or re-elect three new Directors. This year only two of the Directors are standing for re-election, which means that we have a vacancy on the Board.

All Shareholders, aged 18 plus. have the right to stand for election to the AED Board and we would encourage any of you who would like to help to put yourself forward for election. All meetings are held by Zoom so you can contribute from far and wide.

If you are interested, please write a couple of paragraphs about your background and send this, along with a photograph, to info@awesome-energy.com. The closing date for nominations is 14thApril 2021.

We will include this in the information given to shareholders who will be electing the board members. For those who are unable to attend the AGM in person, we will send out all the relevant information, including voting forms.

24th Feb 2021

AGM 2021

The date for the AGM has been set for 15th May 2021 and it will be an online event conducted through Zoom. We will be sending out more information over the next few months, so please save the date.

You can download the draft minutes of the 2020 AGM from our Company Information page Company Information.

Board Meeting Minutes

We are also in the process of uploading all the approved Board meeting minutes to our website. You can currently find and download them on our Company Information page Company Information.

24th Feb 2021

We are currently looking to appoint a part-time Administrator to support the everyday operations of Awesome Energy and its Board members. This would be a remote role and the successful candidate can work from home.

- Financial Reporting & Management

- Liaising with Company Accountants to facilitate Year End Reporting

- Funder Liaison

- Reporting Generation Data

- Document Management

- Board Support

- AGM & Shareholder Management

- Legal Support& Compliance

- Social Media & PR

It is envisaged that the hours will be approximately 16 hours per week and candidates must be willing to work flexibly at key points of the year.

If you know of anyone who would be interested in receiving more information about the role, please pass on the information, or contact us via email info@awesome-energy.com.

21st July 2020

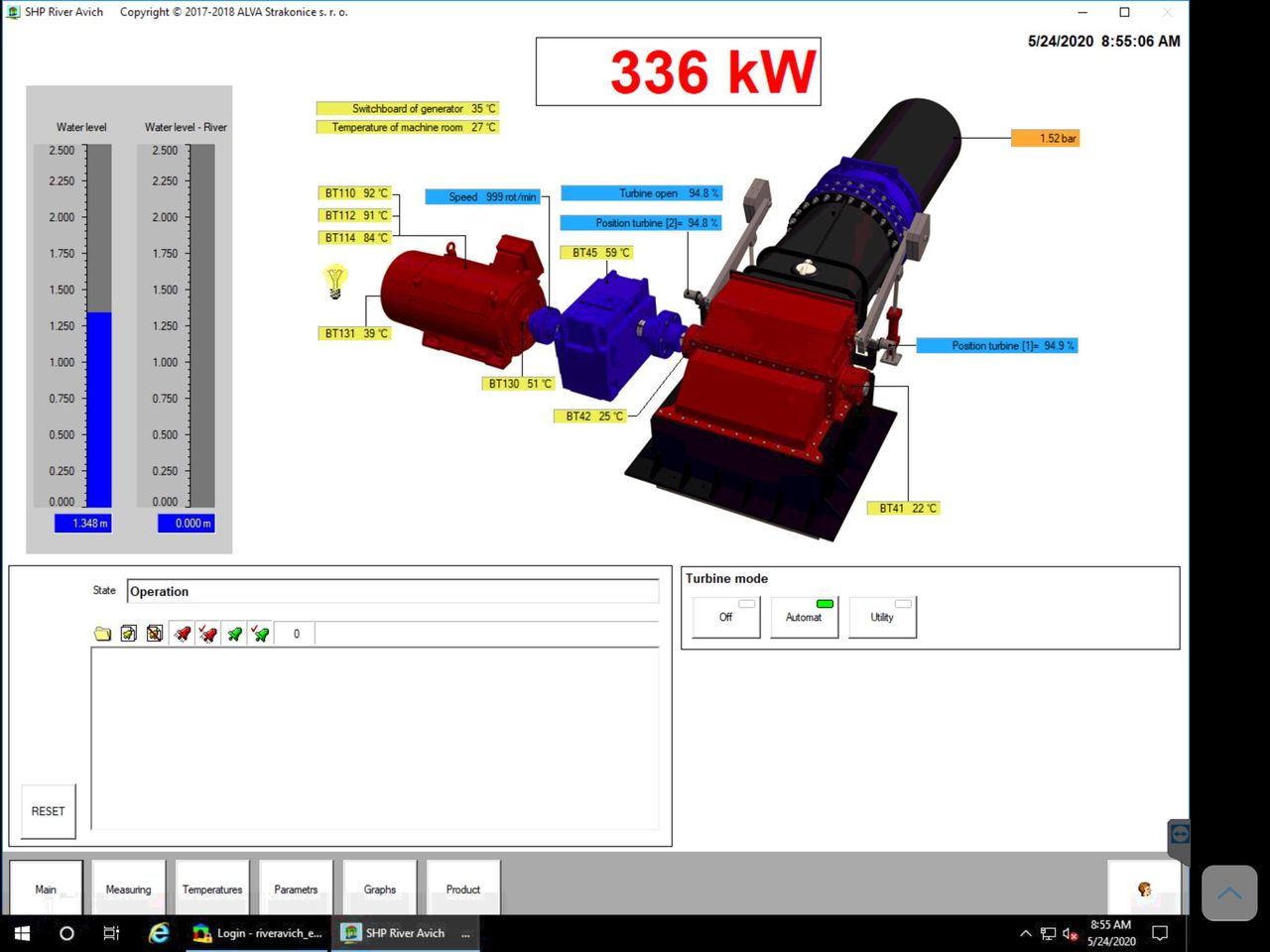

We have on several occasions had both high water levels and hot weather! Strange but true! When this happens the heat generated by the turbine added to the ambient temperature causes the control panels to overheat and the system shuts down. With the help of our good friends the site designers 'Campbell of Doune' and our Electrical Installation Engineers 'IES' we have now installed an extraction fan in one of the ventilation grids. This means that when the power house temperature reaches the 30C, the fan cuts in and runs until the temperature drops below 25C. Much better for the equipment, much easier for operations, and of course, more generation for us. Good news all round.

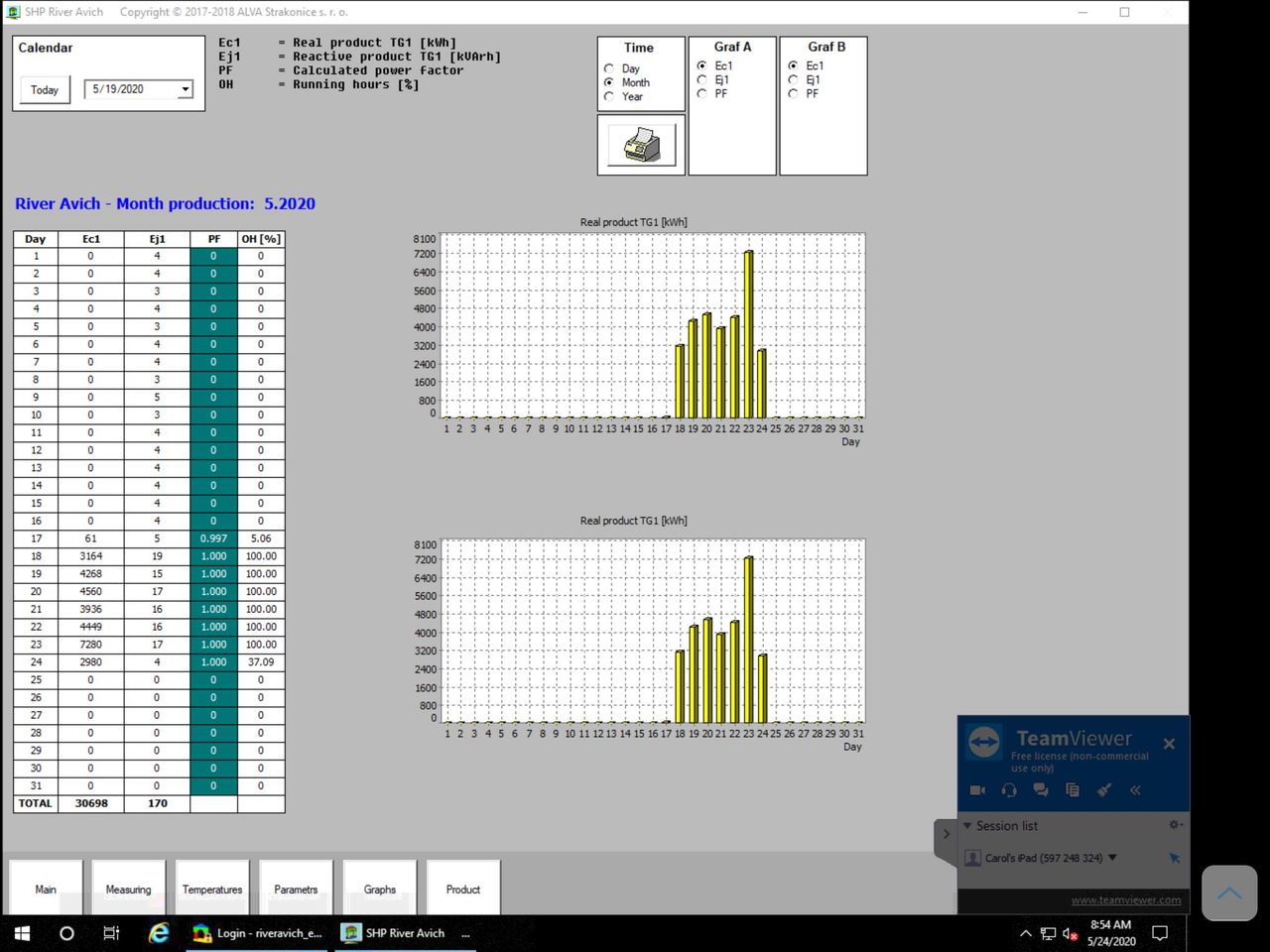

24th May 2020

Sadly for the local folk it’s been a wet and windy few days here in Dalavich! Happily the turbine restarted on 17th May and is still running. Our predictions are for around the 50,000 kWh by month end which would leave us below target for May but still well ahead of plan for the year.

16th May 2020

Our Annual General Meeting was successfully held on 16th May 2020.

Thank you to all who attended and made our first online AGM a success.

Particular thanks to the Directors who presented and to all who posed questions and gave feedback.

Our first virtual AGM went remarkably well.

Reports and documents are now available to download in the Company Information Section.

26th April 2020

Our Annual General meeting will be held on 16th May 2020.

This will be an online meeting, you will be able to ask questions, comment, vote and speak if required, but you MUST register in advance.

Calling notices will be issued 2nd May 2020. Please contact us if you do not receive yours.

12th April 2019

Generation has stopped due to low water.

1st April 2019

Stonking January, February and March with a total generation of 539,436 kWh, which when added to December means that we have already banked 730,402 kWh or 64% of our forecast generation just 4 months into our financial year.

1st January 2019

December was our best month ever at 190,966 kWh which was 158% of forecast and netted us £37k in revenue.

30th November 2018

Investment raised from second share offer totalled £113,300. Thank you to all our investors and supporters.

9th September 2018

In the first 24 hours of prelaunch, investments from existing shareholders and locals £11,000.

5th September 2018

August was our second best generation month every at 123773kWh and earning us around £23500.

29th July 2018

Generation finally restarts! Happy Days!

After over 28 days of low water and zero generation, the turbine kicked into action at 00:04 this morning. We generated over 1800kWh today.

18th June 2018

No rain but the village still had water

When the Hydro was in the design stage a lot of time and effort was spent looking at how to interface the Village Water supply with the Hydro Scheme in a way that would protect both the integrity of the Hydro and the reliability of the water supply for years to come.

The chosen solution was to have two separate pipes running out of the intake chamber, the base of the much larger hydro pipe slightly higher up the side wall of the chamber than the base of the smaller water pipe. The Hydro pipe is huge at 1200mm internal diameter whilst the water supply pipe is 160mm diameter, which is significantly larger than the old 90mm diameter pipe. Both pipes run in the same trench until the top of the hill above the Power House where the water pipe diverts across to the water treatment plant and the Hydro pipe heads down the hill.

The other improvement was to add a scour pipe to the intake to ensure that the bottom of the tank is kept as clean as possible. The Hydro Operations team routinely (once a week) open the valve to a run off pipe that allows water to run out of the bottom of the Intake chamber and back in to the river about 50 meters downstream of the intake. This allows the movement of the water to clean out the base of the tank. The operator can, by checking the quality of the water coming out of the run off pipe, assess the state of the base of the tank.

The intake tank is kept full by water flowing over the bar screen that runs the length of the chamber on the river side of the intake. The river water level is protected by two means:

- There is a compensation slot in the wall that connects the intake to the old weir, this ensures that a certain level of water will always go downstream

- The bar screen is higher on the river side than on the bank side,

this does two things:

- It ensures that most of the river borne debris is washed over the bar screen into the run-off channel, keeping the bar screen clear

- If the river level falls too low, no water enters the intake and it all goes down river.

This solution complied with SEPA’s (Scottish Environmental Protection Agency) requirements but it had one fundamental flaw: What would happen in a prolonged period of low or zero rainfall? The community would be constantly drawing water from an intake chamber that was not being replenished. The intake chamber is large and holds enough water to keep the water supply tanks full for many days, even weeks depending on demand but the team still felt that the risk was too high, as there was a small possibility that the village could run out of water. When pushed the experts admitted that a low probability was a less than 5% chance. Obviously, those of us who lived in the village felt that less than 5% was way too high! So a solution was commissioned and found.

That solution was to put a special intake valve on the river side of the bar screen that would take in enough water to maintain the village water supply unless the river dried up, which is highly unlikely. The valve is a special elbow jointed valve that can be turned 90o to allow it to be cleaned, it sits virtually on the river bed, alongside the bar screen, and in front of the compensation slot, meaning that it takes priority over everything else. It also means that water in the intake tank is constantly replenished at a rate that should keep pace with demand.

The pictures above were taken on 8th June 2018; at the top in the first picture,

you can see the old Victorian weir, showing just how low the river was,

at the bottom you can see the edge of the bar screen which is completely dry,

and the green and silver elbow valve is sitting in the river.

It is, as can be seen in the next photograph, still completely under water.

The bar screen, however, is high and dry!

The Hydro stopped generating on 26th May, meaning that the Hydro was drawing no water at all, leaving the full capacity of the tank, available for the local water supply.

On the 13th June, we had first hand proof that the elbow valve was doing

its work. There is a Head Level Sensor

in the intake chamber, which

records how much water is above the sensor. The senor is located about

5 meters above the floor of the tank. We also have a river level sensor,

situated on the exterior of the intake at the upstream end. Those two

sensors allow us to monitor turbine performance and keep a track of the

water levels.

The turbine will not run if it cannot maintain a head level above 0.5m, nor will it run if it falls below 10% of its generating capacity. It will not restart until the head level is reading 1.22m. On the 26th May, when the turbine stopped, the river level read 1.197m and the Head level was 0.979m. By the 8th June, when these photos were taken, the river levels were too low to allow water over the bar screen.

On the 11th June, the river level was 1.091m and the head 1.049m meaning that the elbow valve was keeping ahead of the local water demand. At its worst, on 13th June at 15:06 the river level was 1.051m and the head level 1.026m.

The river level was 0.146m lower than when the turbine stopped but the head level was still 0.047m higher.

The elbow valve did its job, water supplies were maintained and nobody in the village noticed anything.

The Hydro team are delighted that all the planning, thinking, and desktop scenarios, resulted in a solution which has not only future-proofed the community water supply but which has ensured that the water will keep flowing even in periods of dry weather.

Contributed by: AED Board

Registered address: The Old School - Dalavich - Taynuilt - Argyll - PA35 1HN

Company registration No: #7240

Email: The Hydro Team

Tel: 01866 844160

Copyright © Awesome Energy (Dalriada) Limited - Designed & hosted by Pamela JS Creative